OK, so what you need to understand here is that these kitchen units are my wife's pride and joy. She took her something like five years to decide on the exact ones she wanted. She was getting increasingly anxious about this uneven door and was even considering getting someone in to fix it. I was therefore in line for a whole slew of brownie points if I fixed it myself.

Well, I took out the stuff inside the cupboard (it's one of those on the corner that, through the miracle of engineering, has two sets of trays that are exposed when you open it fully). This didn't take me long. Next, I had to figure out how to move the door around. I suspected that the reason the door had slipped was because there was wear on one of the roller wheels, so if I padded out its track with a strip of folded-several-times paper then that would bring it into line. I tried, but it didn't run very smoothly. So, I figured there was probably an official way to do it and began messing about with various screws.

After about 20 minutes, I had the door off. Well, not completely off because it was still attached by a metal arm to the mechanism and although it looked as if it ought to come off it, the plastic wheel connecting it to the arm seemed worryingly fragile. The last thing I wanted to do was break it, because when my wife found out I'd be spending the next week in hospital (her defence of "no jury would ever convict me" would probably work). Anyway, having done this, the guts of the machinery was exposed and I could see that what I had previously thought was a piece of plastic you were supposed to screw something into was actually itself a stubby adjustment screw. All I had to do was reassemble the door and then give this screw a few turns then I'd be sorted.

It took me another two hours and forty minutes to reassemble the door.

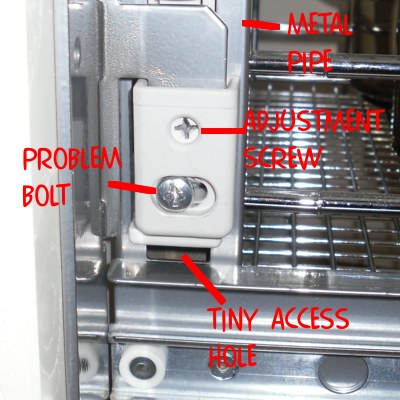

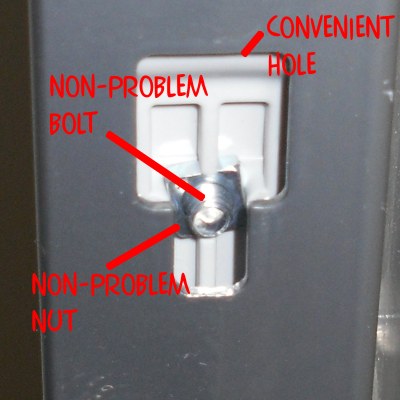

There was this bolt, see. It held the bottom of the door frame onto the door — it was absolutely critical. The bolt went through the plastic frame into the square metal pipe of the superstructure, thereby holding the frame (and hence the door) to the opening mechanism. I turned the bolt and nothing happened. It wouldn't bite. Ah.

OK, well I know what to do when a bolt doesn't bite: wrap it in PTFE thread seal tape to bulk it up. I did this, and sure enough the bolt did bite, but it didn't hold: it just kept turning and turning. It took me 10 minutes to get all the PTFE tape off it once I took it out.

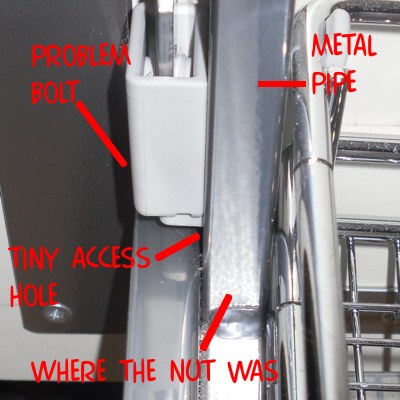

Next, I looked for a larger bolt. I had one that appeared promising, but it wouldn't fit through the hole in the plastic through which the bolt had to pass to reach the hole in the metal. In any case, I had come to realise that the problem wasn't some kind of enlarging of the hole in the metal caused by the weight of the door on it: it was that there was supposed to be a nut behind the metal and it had come loose. It had fallen down the metal mini-girder to the bottom, where the metal was welded onto another piece of metal. It was almost impossible to access. I tried wire, I tried blu-tac on wire, but I couldn't get it. I needed another nut

I checked through my nut supplies, but none of them fitted the particular gauge of bolt I had. Some almost fitted, but not quite. It was probably one of those metric/imperial things. Eventually, just as I was reconciling myself to spending an hour driving to B&Q and back to get a replacement, I spotted an old nut lying around that looked the right size. I tried it, and it fitted! Yay!

I returned to the kitchen and spent the next 15 minutes trying to get it into position. It was hopeless. I had it in a little basket of wire (because I didn't want that nut to fall down the tubing too) but I couldn't manoeuvre it upwards where it needed to go. Eventually, I had to accept that it was too thick.

By now, time was pressing. I hadn't had lunch, but I had to continue with my quest because if my wife got home and found I'd killed her kitchen, there would be blood. I toyed with the idea of taking the entire door assembly off and trying to shake out the nut that I knew was inside, but I didn't want to risk breaking the plastic wheel I'd have to unfix to do so.

Then, I had the idea of using a magnet. Was the nut magnetic, though?

There were two bolts. The one at the top was fine, it was the one at the bottom that was the problem. On the other side of the metal pipe from the top bolt was a piece of plastic from which the trays inside the cupboard had been attached. I could slide that open and have a look at the top bolt from behind. I slid my thumbnail behind the plastic to pull it off, inso doing jamming it right up under the nail, separating it from the flesh. That's going to sting for a few more days yet. Anyway, I got it off, found the nut (it was square) and pulled it out with a pair of pliers, having carefully arranged some wire at the bottom of the pipe so if it fell I would catch it before it got to the inaccessible part. It came out fine anyway. I checked, and it was magnetic. Great! Equally carefully I replaced it, then went to get a magnet.

The metal frame was also magnetic, so I couldn't manipulate the nut through it. I somehow had to get the magnet down the pipe into the recess. Sadly, the magnet was too big to go through the gap. All my magnets were too big to go through the gap. Was I going to have to make an electro-magnet?

Ha! I knew keeping all those electric motors from old razors and stuff was a good idea! They have permanent magnets in them! I took one to pieces and smashed a magnet up with a hammer until it was small enough. I spent 10 minutes trying to drill a hole in it (I didn't even manage to drill a scratch in it) then went on to constructing a wire cage for it and lowering that inside the metal pipe.

I successfully retrieved the nut. Yes!

Now, all that remained was to put it where the bolt could find it and screw the two together. This would have been easy if I'd had the access to the bottom bolthole that I had to the top one, but I didn't. I couldn't get to it from the hole below, but I could get in from a hole about 4cm higher up on the other side of the metal turb. Unfortunately, it was too dark to see inside the pipe so I had to use a torch. The next, oh, I suppose half an hour or so was spent trying various methods of lowering a nut into place then holding it while I got the bolt to connect with it. Wire didn't work, because to hold the nut in place it got in the way of the bolt. Blu-tac on wire didn't work because I couldn't see where it was going even with a torch in my mouth. Adhesive tape would have worked, except that it was too hard to control. Adhesive tape on wire (earth wire I took from a cable used to carry 30 amp current to cookers) did work, in that I could line up the nut, but it wasn't strong enough to stay still when I tried to screw the bolt into it.

Eventually, I lowered the nut in place then speared it from the other side with a bradawl (a screwdriver being too imprecise). Holding it now with the bradawl, I was able to stick a screwdriver in from the backto push it into its socket. Removing the bradawl, but still pressing on the nut with the screwdriver, I managed to screw the bolt in and have it bite. This done, I swiftly reassembled the door.

I then spent 9 seconds straightening it.

So, my life was saved and I got the brownie points. I missed lunch, but hey, that's what Cadbury's crème eggs are for.